![]()

~FOR

SALE

~ THIS HOME & LAND 7Acres ~ FOR SALE~

Using the age-old technique of HAND TAMPER

Rammed Earth Building is both evolution and revolution.

Its origins date back ten thousand years.

Stabilised rammed earth is a strong and durable construction method, is weather resistant, thermally efficient and maintenance free.

Stabilised earth construction is solid and natural from the ground up.Earth building materials costs are 'dirt cheap', often an important consideration for owner builders. Although it is based on a ten thousand year old tradition,

stabilised earth inspires non-traditional contemporary thinking.This is because it is a medium which invites individual expression.

While it also combines well with conventional building materials, it is a plausible alternative in its own right. So the possibilities are endless....Rammed earth, stabilised earth, nouveau pise, new terminology for a building technique that has stood the test of time.

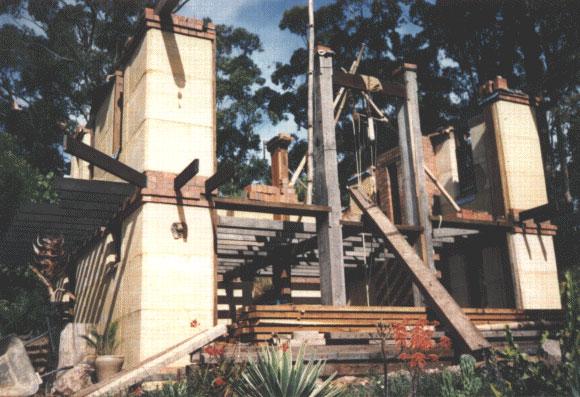

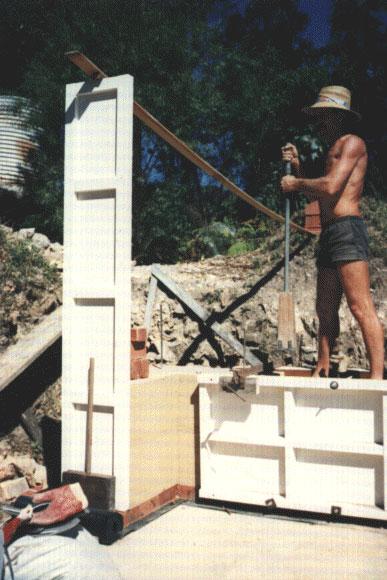

Formwork

Corner Form

Set in place & ready to take the first layer of earth.

Note the tall vertical form at left, which will be left in place for all three horizontal layers that bring the wall to ceiling height. This vertical form has a key way attached that allows the form sections either side to join.The inside faces of forms were painted with vege oil as a release agent.Lengths of reinforcing rod can be seen protruding from within the form. With each new form, rio-rods were welded on to extend up through the wall sections. A final length of threaded rod is welded & protrudes above the wall enabling the roofing plate/beam to be bolted down.

This corner form will produce a wall 450mm thick & requiring over one tonne of earth. Building codes for one storey houses only require 300mm thick walls. My heavier gauge walls really increase the insular cosiness inside, especially during extreme weather.

This home weighs over 80 tonnes but the standard cement slab only required some extra steel reinforcing rod, luckily I am blessed with a good ground rock base.

Hand Tamping Begins

Coffin Form

Ramming an upper section of wall in the coffin form. Notice how the coffin form is clamped onto the already rammed corner. Corners of walls are the starting points, other sections follow on. Adding further sections to the structure may take place as soon as one can reset the form, there is no drying time required. Threaded rods clamp the form together, along with furniture clamps where the coffin form overlaps the outer faces of the earth wall. Two threaded rods holding the two sides of the timber form together at the base become earth-rammed in place and need to be unscrewed from the just completed earth-wall section. This is done by locking two nuts at rod end then simply unwinding.Use of a high torque electric reversing drill is recommended.

Australia's Heritage

Rammed Earth Houses

In Albany, Western Australia, the oldest rammed earth building is

Strawberry Hill Farm built in 1830.

Parts of the building were rammed by hand with no cement added.

This farmhouse remains perfectly sound and is classifed by the National Trust.

A fine example of rammed earth's durability

Strawberry Hill had NO added Cement Stabilisation as today's R.E. buildings.

Some pioneers used an earth ad-mixture from termite mounds

which added a binding medium to the earth.

The termites masticate the earth with a saliva agent that makes

their mounds tough & resilient to weathering

Rammed Earth Benefits.

Rammed Earth, probably the most sustainable form of wall construction.

Requires minimal energy consumption in the process compared with alternatives.No fossil fuel consumption, as in baking bricks. No processing of artificial materials

or added paper as in Gyprock (plasterboard) & Chipboard.

Minimal use of timber and milling energy.

Minimal use of expensive Portland Cement & associated C02 emissions & mining.

No 'sick building syndrome' or gasses emitted in man made building products.Rammed Earth has a HIGH LOAD BEARING compression capacity

compared with other methods of earth building.

Winching third storey beam into position

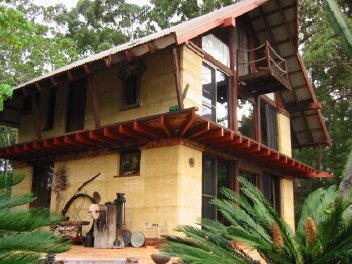

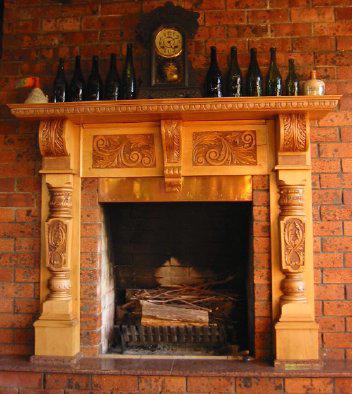

The aesthetics of rammed earth create an incomparably warm natural ambience.

Structurally with 45cm walls, I may have added further storeys to the building

with rammed earth's high load bearing capacity.The only finish, interior/exterior required is a one off spray with Bondcrete-(TM)

Or a commercial silicon product for exposed walls, overall maintenance is minimal!Plus the added advantage of constructing the walls

directly from the raw material means no brick laying.

House bricks are enormous consumers of energy in forming, firing

and cartage to retailer then to the home site.

Rafters going up...

~~

~ built with local material & labor

~ owner builder cost effective

~ stabilised interior humidity

~ virtually maintenance free

~ beautiful natural aesthetic

~ planet earth friendly

~ timeless beauty

~ load bearing

~ fire proof

~ termite proof

~ seismic safety

~ in-situ construction.

~ low carbon footprint

~ 100% organic material

~ highly cyclone resistant

~ healthy living environment

~ energy efficient high thermal mass

My home construction.

Construction of the two storey, 45 cm. thick walls

took place part time over a leisurely 18 month period.The walls were hand rammed within light-weight and easy to handle

wooden forms made of 19mm or 3/4in flooring ply and pine studs.

Comprising a corner form and a coffin form.

Hand ramming has given the walls a high grade of compaction.Disappointingly some commercial builders of R.E. with financial,

time & bank pressures are not achieving good grades of earth compaction.

Often adding much more than the correct standard benchmark of

100mm (4 inches) of loose earth layers to forms before each compaction.

This errant sub-standard practice is devaluing Rammed Earths reputation!

Railway sleepers were used for door and window jambs/ lintels.

The rail sleepers were incorporated into the earth forms and

mechanically attached to the earth wall sections.

Sleepers also assisted the follow-on upward forms to be set.The earth I used is a low grade bricklayers loam

light yellow in colour & was trucked to my site.Light coloured Earth was intentionally chosen to keep

a light reflective ambience inside the house.Deformed reinforcing rod is incorporated vertically through the structure.

The steel rio-rod is anchored to the cement slab foundation.

This gives good earthquake resistance & structural cohesion.

The rio-rod is then tied off at the roof plate making the walls

and roof of the house highly cyclone resistant.Stable second hand massive hardwood beams were

used for the roof plates and internal spans.

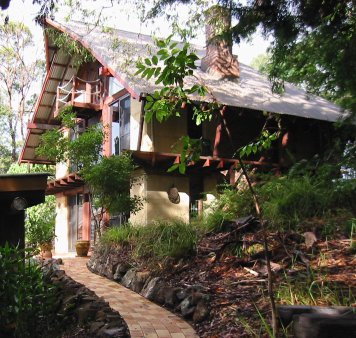

Passive Solar Design:Consideration of passive solar design in building is

important in the climate of global warming.We are all individually responsible for minimalist energy consumption, where

better to begin but in our homes where the majority of our time is spent.

It is also to our longer term financial advantage to lessen energy costs.

Orientation AWARENESS of your building block is essential to your plans.

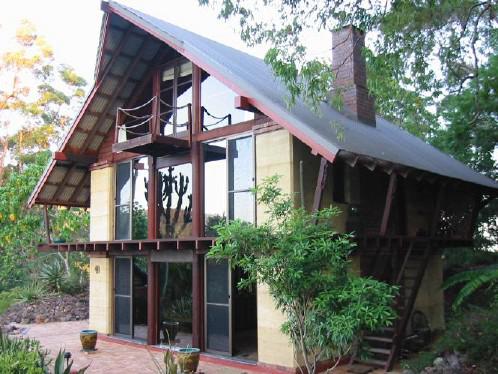

The North and solar facing front of this building is fitted

with hi-tech solar guard glass. This eliminates 85% ingress of solar heat

during the day but retains warmth at night.Ground Floor photo above shows the south facing windows when opened,

allow cooling south winds to flow through to the upper floor,

where they exit via north facing french doors during summer,

In Australia & southern hemisphere sunlight & warmth come from

the north, this needs to be the first consideration when planning

and orientating your intended home.

Air and light well

An internal air and light well ensures warming of the whole house

in winter and permits a cooling airflow in summer.

As well the 45cm thick walls keep an even temperature moderation

inside the home compared to the rise and fall of the exterior climate.

This conscious passive solar design makes the building energy efficient.

Further...

Cantilevered verandahs are incorporated around the second floor.

To allow verandah joists through the rammed earth walls

corbelled brick work was used.Over 80% of the building work was completed by myself.

I had help to lay the concrete slab and to raise the roof.

The challenge of lifting large beams into place was basically performed

by Tirfor Winch, bamboo tripod & brain cells.Standing the two five metre 22cm x 45cm hardwood beams

at the north glassed face was memorable.My home is situated on the western border of Byron Shire

Northern NSW with a view of the Border Ranges and Queensland.

Thus the over engineering of the structure, especially the rammed walls,

provide a protective comfort zone of tranquility

and safety in both serene and extreme weather.

This building has now been withstanding the elements for over thirty years!

As maintenance goes, little has been done.

Some repainting to the exterior woodwork.The earth walls are showing no weathering and I can only conclude that this

structure will be here long after I shuffle off.The promotion of sustainable, low cost & energy efficient housing is

a most important cause in the use of finite natural resources

on over populated planet EARTH.

I am available to consult with any owner builder intending

to create a rammed earth home.

Please contact me at the email address below for

assistance in your Rammed Earth project.

~ It takes hands to build a House. But only hearts can build a Home ~

This NON PROFIT-ADD FREE web-site has helped

owner builders around Planet EARTH for 30 years.

PayPal-Donation to support this site would be greatly appreciated

to offset ISP - web-hosting - software - computer costs &C.

THANKS SO !!.

<